Urban Sanitation in Bangladesh - Component 4: Treatment, disposal and reuse

Every garbage dump is an investment

Our SNV learning and demonstration project started with the capacity building of the local government (component 3), aiming to create a climate of good governance for safe emptying, and to raise demand and supply for safe sanitation (see component 1 and component 2). Our efforts went further, to be able to meet increased demand for safe sanitation services (component 4). You know, it’s like the chicken and the egg, the one cannot do without the other, and wondering what comes first is fairly useless.

In 2015, the BMGF provided funds for a treatment plant that could process up to 15% of sludge generation in Khulna. This treatment plant can be expanded step by step as demand grows. Ultimately, the investment costs for universal coverage in sludge treatment for Khulna are estimated at five (5) million dollars. Compare this to the whopping 158 million dollar needed for a sewage based investment that would cover a mere 60% of Khulna (KWASA 2017). This tremendous cost difference stems from the fact that most households have built pits or septic tanks to collect their faecal sludge, for lack of sewage. We took this existing situation as a starting point for our approach. The enormous cost difference between sewerage and on site solutions has also been found in other places, as this report by BMGF shows.

Although treating faecal sludge on-site requires considerably less funds than building a sewage system from scratch, the necessary investment is still considerable for cities in this region. Technical options were therefore prepared and selected in a process of informed choice, taking into account wastewater and/or sludge volumes, their characteristics, and re-use potential.

4.1 Field survey: Providing sludge Characteristics

We are in deep shit, and we must stop ignoring it

Before advancing on the construction of a treatment facility, we gathered field data that would help us to create the right design of the plant. First, we calculated the quantity of the sludge. According to the field survey the faecal sludge volume generated in Khulna, Jhenaidah and Kushtia is respectively 710,000 m3; 58,705 m3; and 104,581 m3 per year.

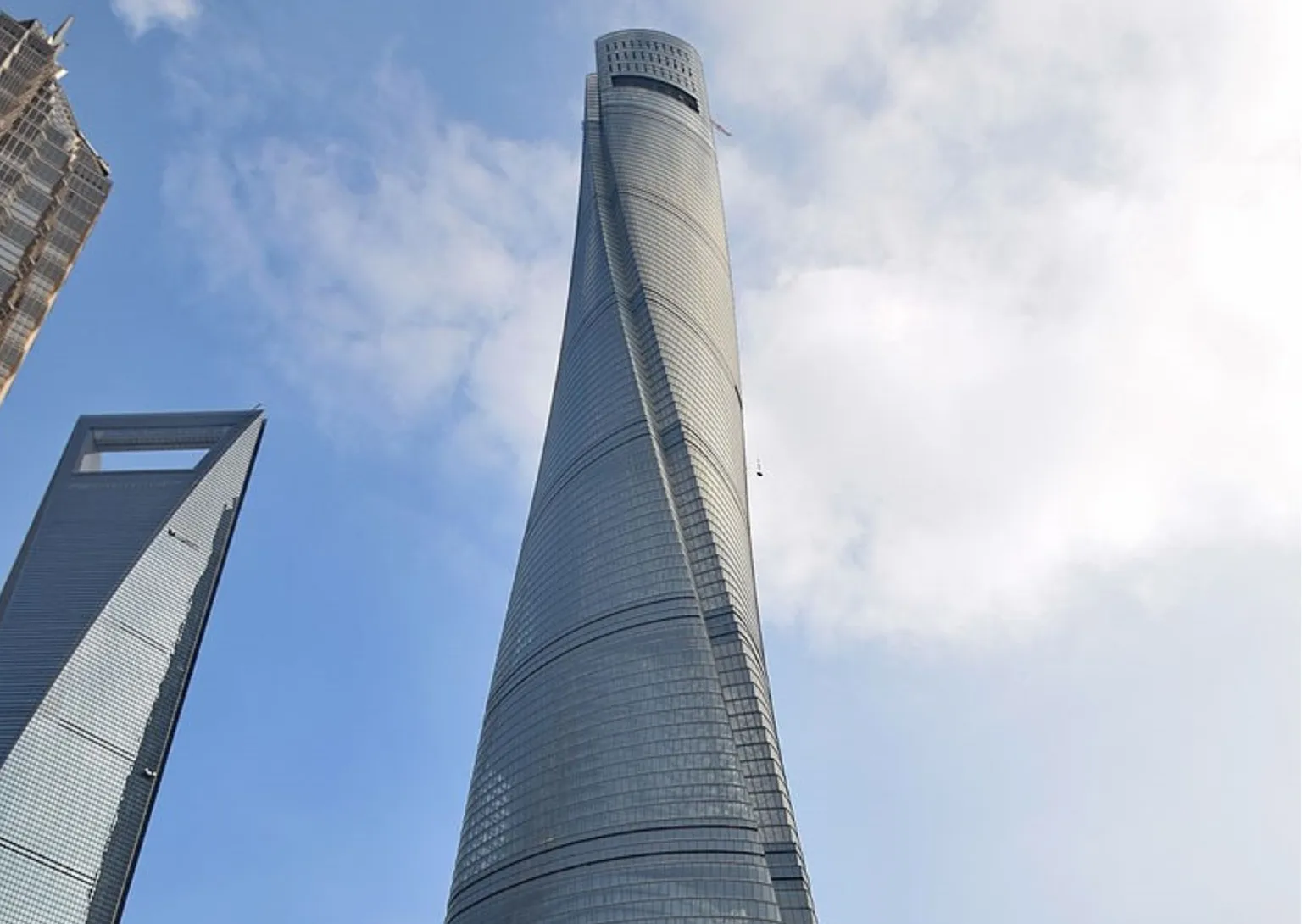

Just to give you an idea of what we are talking about; the Shanghai tower is one of the highest towers in the world, counting at 630 meters. Imagine a slightly bigger tower, just as broad and deep as it is high - there’s your annual faecal sludge for the city of Khulna alone. And on the list of cities in the developing world, Khulna is small scale compared to the rest. In 2016 the world counted 31 megacities with over 10 million inhabitants (24 in the less developed world) and over 1.000 cities with over 500.000 inhabitants each. Almost one quarter of the global population lives in cities with over 1 million inhabitants. And in many of these cities, sanitation is not managed properly. In other words, we are literally drowning in a sea of shit. And whereas the Shanghai tower reaches out its bright and shiny pinnacle towards the skies, this murky sea flows underground, contaminating its surroundings unseen, and creating a vicious cycle of disease; diarrhoea, malnourishment; while locking people into life-long disadvantages such as poor physical growth, hampered cognitive development, less earning potential and ill-health. This is why we need to close the sanitation gap.

How about the characteristics of the faecal sludge? We literally went out into the fields to collect samples of sludge for each of the three municipalities involved in this project. Characteristics were determined for each sample, experiments were performed on sixteen wastewater quality parameters, such as; solids concentration, chemical oxygen demand (COD), biochemical oxygen demand (BOD5), nutrients, pathogens, etc.

Let us dazzle you sanitation nerds with a few facts: “The Solid contents in faecal sludge of the three towns varied between 3% and 6%. The range of COD concentrations were 7600-9600 mg/L. BOD5 concentrations were a whopping 819-1662 mg/L, whereas the acceptable limit for disposal into inland water bodies is only 40 mg/L (ECR, 1997). Thus, it was a significant challenge to reduce the BOD5 in the faecal sludge treatment plant for its ultimate disposal.”

Put simply, if waste contains a lot of organic material, you can decompose it naturally by using specific plants that accelerate the process. The end result can be used as a soil conditioner. But if the waste contains a lot of chemicals you need to add extra treatment to the process – as is the case in Europe where waste is bubbling with chemicals from shampoos and soap, because all the wastewater is collected together. In Bangladesh, where wastewater from tap and septic tanks is collected separately, faecal sludge mainly consists of organic material. Which by the way does not mean that it is free of pathogens, it is just easy to decompose in an organic way.

4.2 Feasibility Study: selecting the right technical option for the plant

The organic way; letting rocks, sand and flowers quietly decompose sludge

A feasibility study was conducted for all three towns on a short term faecal sludge treatment plant (FSTP). The Khulna University of Engineering & Technology (KUET), the Asian Institute of Technology (AIT) and University of Science and Technology Beijing (USTB) jointly analysed the current context of these towns and cities in terms of their population, land use and sludge volume. We used these results to support the city authorities decision on design, construction and operation & maintenance of short-term treatment options.

Our scientific partners helped us to point out the technical options for the treatment plant, and from these options the city council chose ‘constructed wetlands’ for Khulna and Jhenaidah, because of their low capital and running costs. Kushtia already had a drying bed with co-compost facilities. Jhenaidah had a non- functional plant.

Just to give you an idea, alternative solutions would have been: a biogas installation, waste stabilisation ponds or an omni processor (that is high tech dewatering technology, using biosolids to produce electricity and clean drinking water as output. Want to see Bill Gates drink water from human waste? See this video.

Shanghai tower

Abandoned FSTP at Jhenaidah

4.3 Construction of the treatment plant:

A second life for former garbage dumps

The Asian Institute of Technology (Thailand) and the Khulna University of Engineering & Technology were the technical service providers in the design of the faecal sludge treatment plants (FSTP) in Khulna and Jhenaidah.

To build the treatment plant, Khulna and Jhenaidah allocated plots that formerly had been in use as garbage dumps for solid waste (so-called passive landfill plots) within their dumping site. This posed a challenge for the construction of the treatment plant, because the soil was so soft that it could not carry heavy weights. This did not discourage us, instead we took the opportunity to demonstrate that it is really possible to construct a good treatment plant on a passive landfill site. Using former garbage dumps like we have done, can be a good example for other cities. As we mentioned before, Bangladesh is densely populated and land is becoming scarce. Besides the country is scattered with former garbage dumps.

We faced several challenges while building the plant. It took quite a while to prepare the land properly. The unstable soil needed to be compacted up to fall within a permissible limit to be able to carry the weight of the construction. When the soil was finally ready, we started constructing the embankments for the drying beds, where the sludge would be deposited and treated. Due to the soft soil, we decided to construct earthen embankments instead of concrete structures. This type of construction was a first-time experience for everyone involved such as the contractor, sub-contractor, masons, labourers as well as the SNV team. They knew about ponds, but not about plastic sheets and our new innovative filtering system. As construction progressed, many lessons were learned along the way. We considered the quality of the drying beds key, and therefore devoted a lot of time and effort to ensuring the quality and workmanship of our labourers. One of the major challenges we faced during the construction was collecting the necessary materials, as those were not generally used for construction.

Jhenaidah already had a treatment plant, but not a single drop of sludge had ever been taken in. The plant was lying idle when we inspected the premises and concluded that it needed a serious upgrade. We added a second basin only for liquids.

Biosolid in a basin, purified by using flowers

Cleaning for upgradation of Jhenaidah FSTP

After two years of hard work, the plants finally got up and running between December 2016 and March 2017.

A closer look at the information sheet in Khulna

4.4. Operation of the plant

On 16 December 2016 and 4 March 2017 respectively, the first truck with faecal sludge entered the Jhenaidah and Khulna treatment plants. And many trucks followed thereafter. To date 1.5 million litres faecal sludge from Jhenaidah and 0.9 million litres faecal sludge from Khulna have been safely emptied, transported and treated.

Deposits of faecal sludge are registered in a log-book and a GPS tracking system has been installed in every truck, to monitor them remotely in the IMIS tool (we discussed in component 3). Yes we can even check these trucks from our cell phone! This is important, because we need to be sure that their load is emptied specifically at the disposal side and not somewhere in a ditch. SNV developed guidelines for maintenance and operation, and the staff of the plant have been trained on different procedures. For now, Khulna FSTP is being operated by the City Authority, and a process of outsourcing services has been initiated, as you could read in the story of component 2 (link). Operation and maintenance in Jhenaidah FSTP have already been outsourced.

Sludge inlet for trucks and vacutugs

Real time monitoring of trucks

At this moment operations are running smoothly. The treatment plants have the capacity to treat up to 15% of Khulna’s and 18% of Jhedaidahs faecal sludge, but only a small portion of its capacity is in use. Ultimately, the success of our approach will lie in the uptake of demand, which is why the awareness campaign we mentioned in component 1 is essential. In the end it is not technology, but people who generate breakthroughs.

The proof of the pudding will be in the demand for sanitation services, which takes us back to component one.

The caretaker of the plant, “People think it is a park.”

4.5 Action research

There is nothing fishy about well treated sludge, it is filled with nutrients!

Countries like Bangladesh, have strict religious taboos around shit. It is low grade, should never be touched and even showing the downside of your feet to somebody else is seen as an insult. In this context re-use of faecal sludge must be approached with the utmost care. One thing we needed to be sure of, is the absence of pathogens in the treated sludge (contrary to the raw faecal sludge that has been used for centuries, despite all the taboos).

On the positive side of the coin were the nutrients that benefit crops and fish. SNV concluded that although treated sludge contains less nutrients than commercial products, the price quality ratio is actually very positive.

Action Research on Co-composting of Faecal Sludge and Municipal Organic Waste for Sustainable Crop Production in Southern Bangladesh

Action research was formulated with the Bangladesh Agricultural Research Institute (BARI) to generate scientific evidence for the safe use of treated faecal sludge, co-composted with municipal waste as soil conditioner. We tested four vegetables - cauliflower, cabbage, okra and pumpkin, and 2 flower varieties. Results indicate that a mixture of organic and inorganic fertiliser gives the price-yield optimum.

These findings, confirm that we can meet the demand for re-use of faecal sludge to compost from larger organisations (as we have described in component 1.2.) with safe supply. Selling faecal sludge as soil conditioner opens the way to generate extra income that can be used to scale up safe sanitation.

Read more in this paper: Co-composting of faecal sludge and municipal organic waste for sustainable crop production in southern Bangladesh

Action Research on Impact of Treated Faecal Sludge on Fish Growth and Associated Health Risks

Similar to crop production, faecal sludge can be used as fish feed or plant nutrient in aquaculture. Remember that Bangladesh is one of the largest fish exporters in the world. An action research was designed with the Fisheries and Marine Resources Technology Discipline of Khulna University and World Fish as Knowledge partner. The goal was to provide empirical data to support policy-making on the reuse potential of treated faecal sludge in aquaculture.

First of all we found that no e.coli bacteria could be detected in any of the fish gut that were tested. Secondly, we experimented with several ratios of faecal sludge and commercial fish feed -which is much more costly. Fish could survive on a ratio of 75% sludge and 25% commercial feed, albeit with little growth. We concluded that a 50%-50% ratio gives the best price-quality outcome. Since the commercial use of faecal sludge for fish feed hasn’t met much enthusiasm to date, we have decided to put further tests on hold. But we can continue any time.

Read more about our research Paper: Impact of treated faecal sludge on fish growth and associated health risks

Wrap up of the components in our programme

We have taken you through the 4 components of our urban sanitation management programme, funded by BMGF. These components are the key to our comprehensive approach towards city wide sanitation.

We have shown that consumers are willing to pay for safe desludging when made aware of the risks of current habits. We have worked with the city authorities to launch a ‘demand creating’ publicity campaign. Citizens now know sanitation service exists, and they know how to call for it.

We have shown business models, indicating that safe sustainable services are possible. We improved the working circumstances of manual pit emptiers.

We have worked together with the city authorities and line departments to put regulations in place, and reinforce them, to collect taxes, and launch a proper desludging service.

We have established a faecal sludge plant that treats sludge up to the point where it can safely be re-used as soil conditioner or fish feed. The capacity for treatment can be scaled as demand grows.

Let us go back to the goals we formulated at the beginning of the project:

SNV assured that 250.000 people have access to environmentally safe sanitation facilities, improving the environment of one million people. Plus, by taking along relevant stakeholders, we have paved the way for continuity, replication and upscaling of our findings.

But we are far from leaning backwards. The last mile is always hardest, so we must continue with extra effort. We must scale up our approach towards city level and stir up actual demand for sanitation services. We described how we launched a four month awareness campaign, how we organised events in every slum of the city. But awareness is never enough to change deeply rooted habits, we must handle both the carrot and the stick. The city authorities must put pressure as well, enforcing compliance to sanitation rules. At the same time we must reach out to people who cannot afford sanitation services, especially in slums. We must work with slum committees, going door to door and mobilising people to check out communal toilets. We want to leave no-one behind! Next to household level we must start direct interventions in schools and hospitals, so that they can set the example.

So much left to do! That is why we are very happy to announce that BMGF granted us Phase 2 of the project, allowing us to scale our work towards city-wide inclusive sanitation services in Khulna. Khulna has been selected as one of the six model cities for implementing BMGF city wide inclusive sanitation engagement (C-WISE) programme. C-WISE prepares cities for investments in sanitation, and works with them to materialize this investment. For Kushtia and Jhenaidah we will continue providing light support to ensure the functioning of services. We will continue to contribute to the development of national guidance on urban sanitation, and the implementation of safe inclusive slum sanitation services with different development partners under the National Urban Poverty Reduction Program (NUPR).

The formal launch of Phase 2 is expected to take place in March 2018, after approval from the authorities in Bangladesh.

You will soon hear from us again!